Project: Design Fluke tool

Tool: Electrosurgical Analyzer

Time: 11 weeks

Team members: 3

Electrosurgical Analyzer: Analyze Electrosurgical Units (generators used to cut and coagulate tissue)

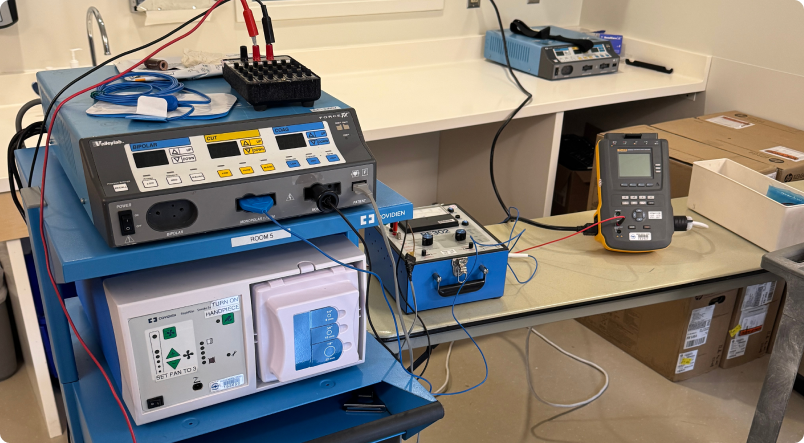

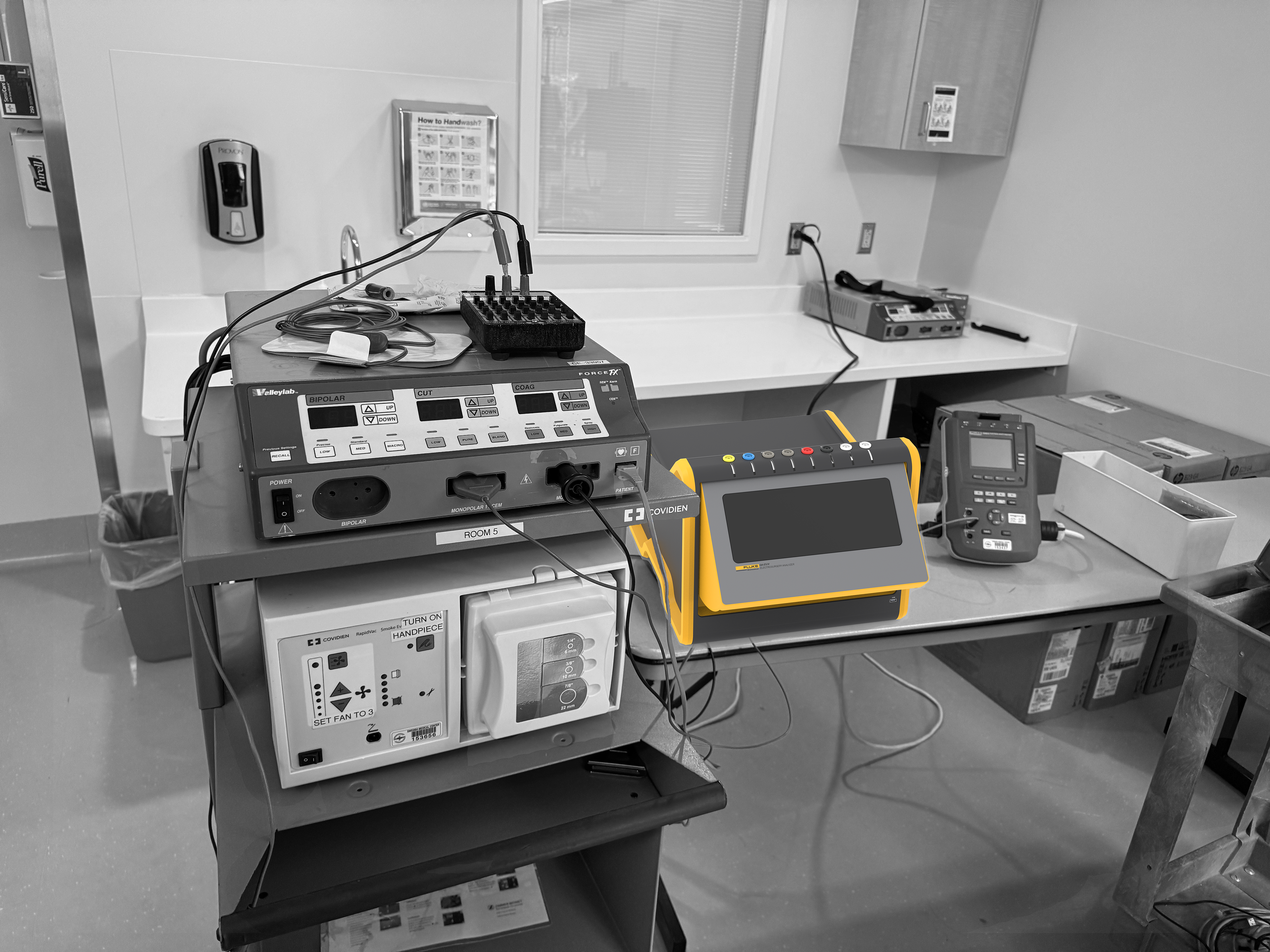

We started our research online and decided we needed to get a feel of the scale and how the hospital technicians do their jobs when testing the electrosurgical units. We made some cardboard models after not being able to get into any hospitals to see the process first hand.

After some waiting, we were able to visit two hospitals to watch the testing of the Electrosurgical Units. They are the generators used in 85% of surgeries that cut and coagulate tissue. The Electrosurgical Analyzers are what test those units to make sure they are good for surgery. Each unit in the hospitals must be tested every 6-12 months in a process that could be improved.

Pain Points:

- Complicated Testing

- Varying Set Ups

- Long Test Times

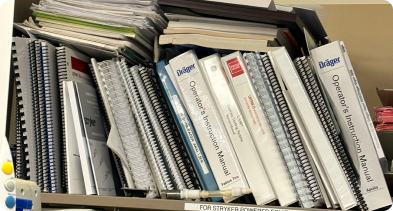

- Many Manuals and Cords

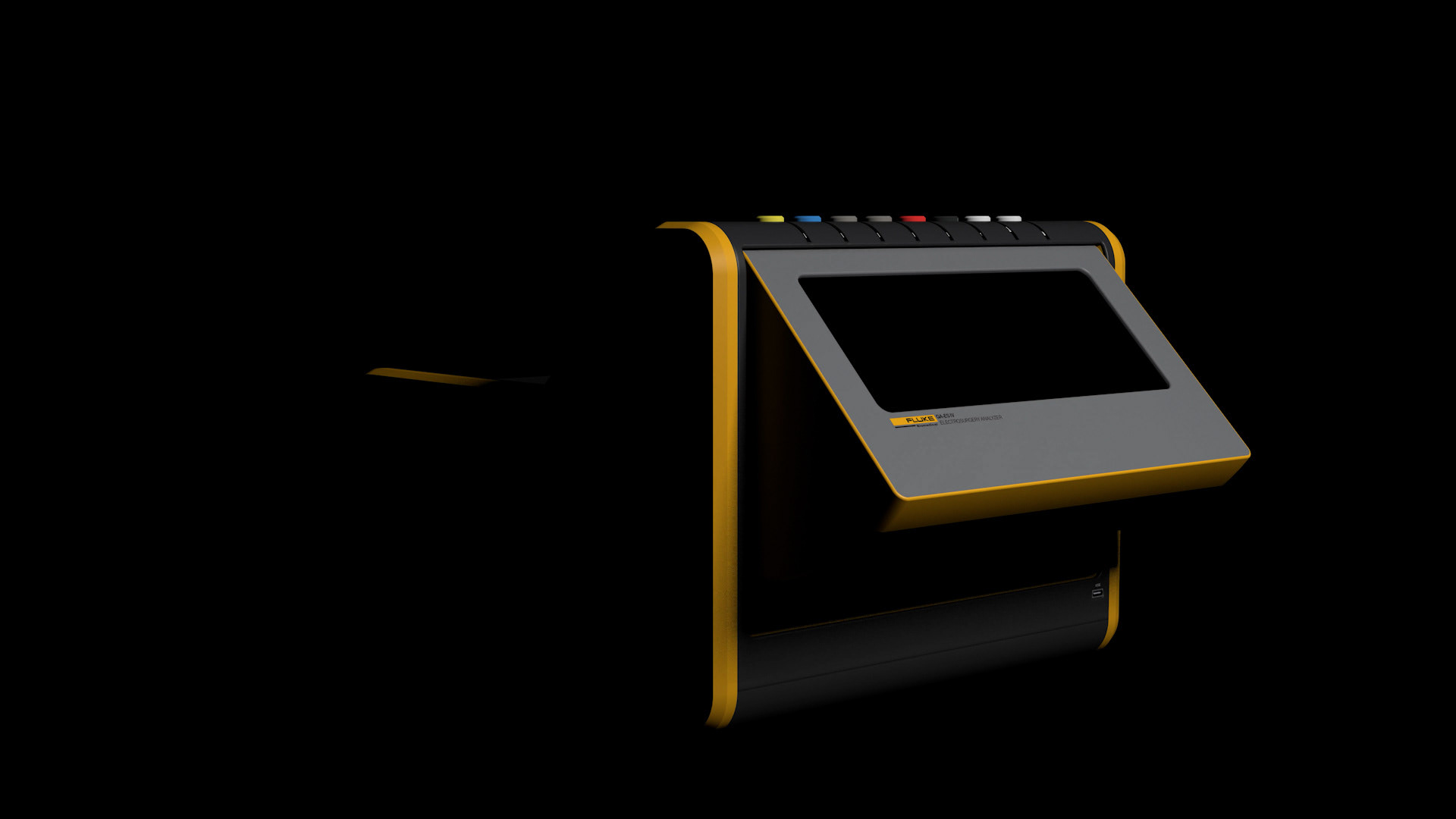

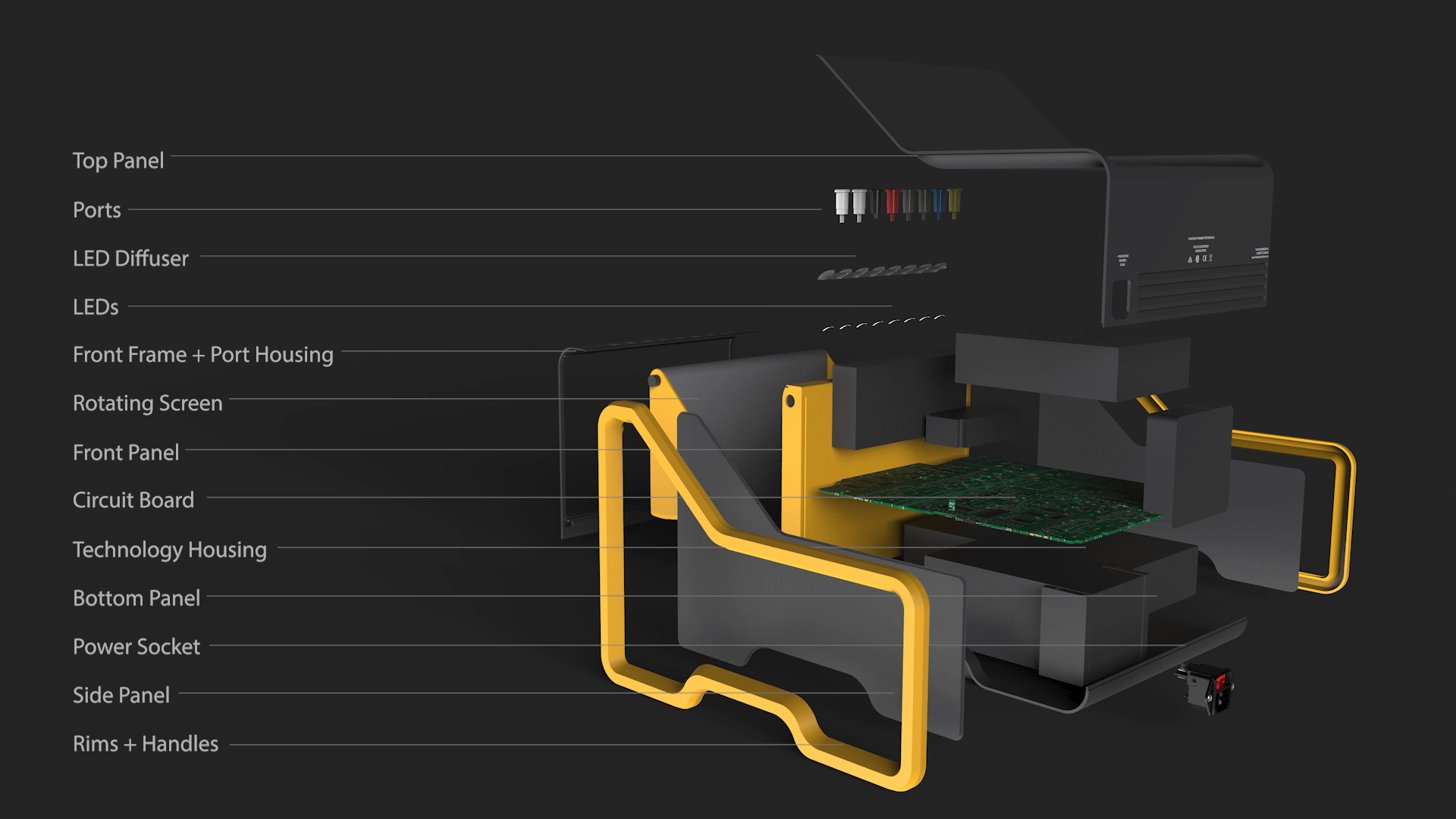

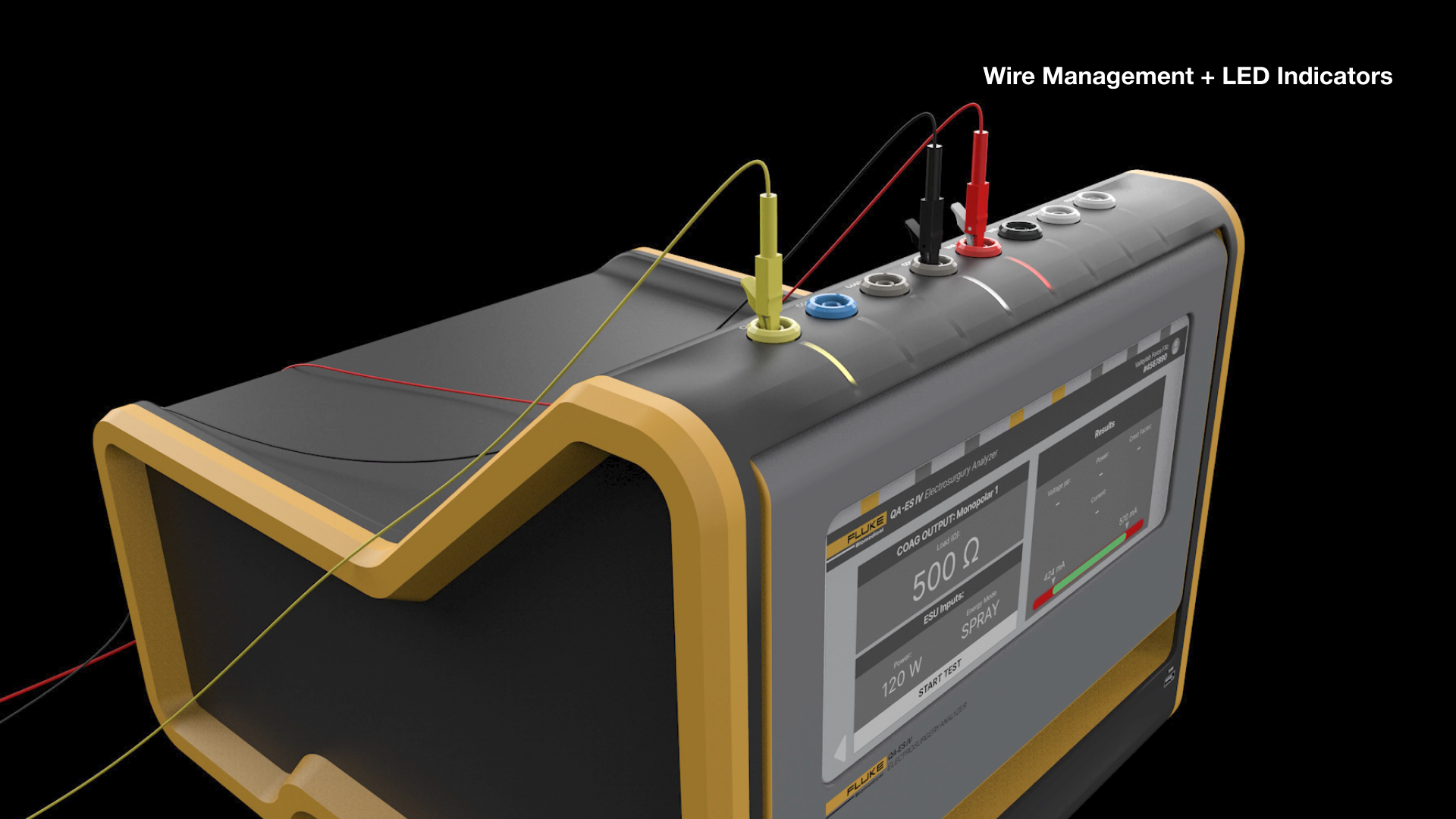

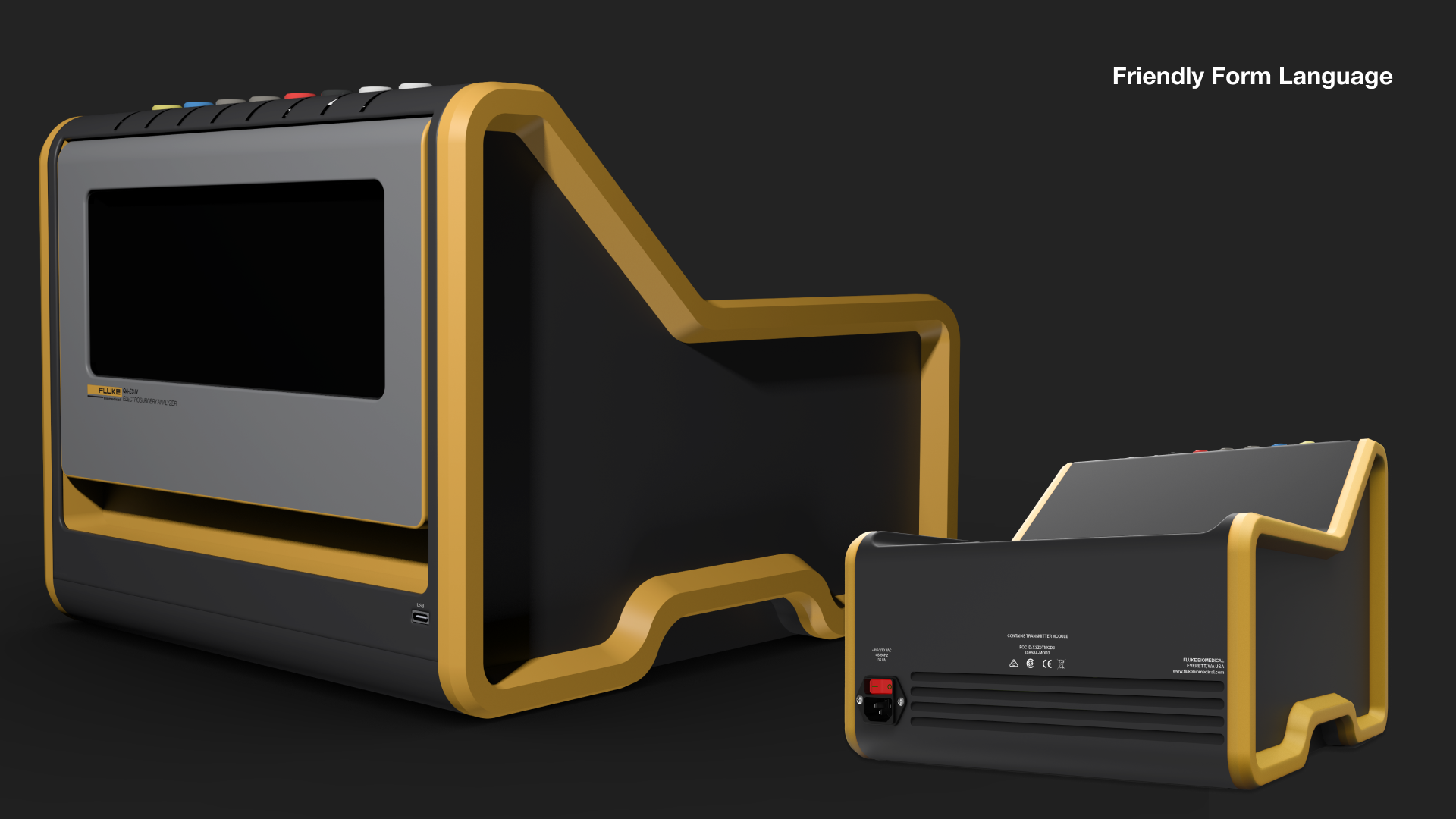

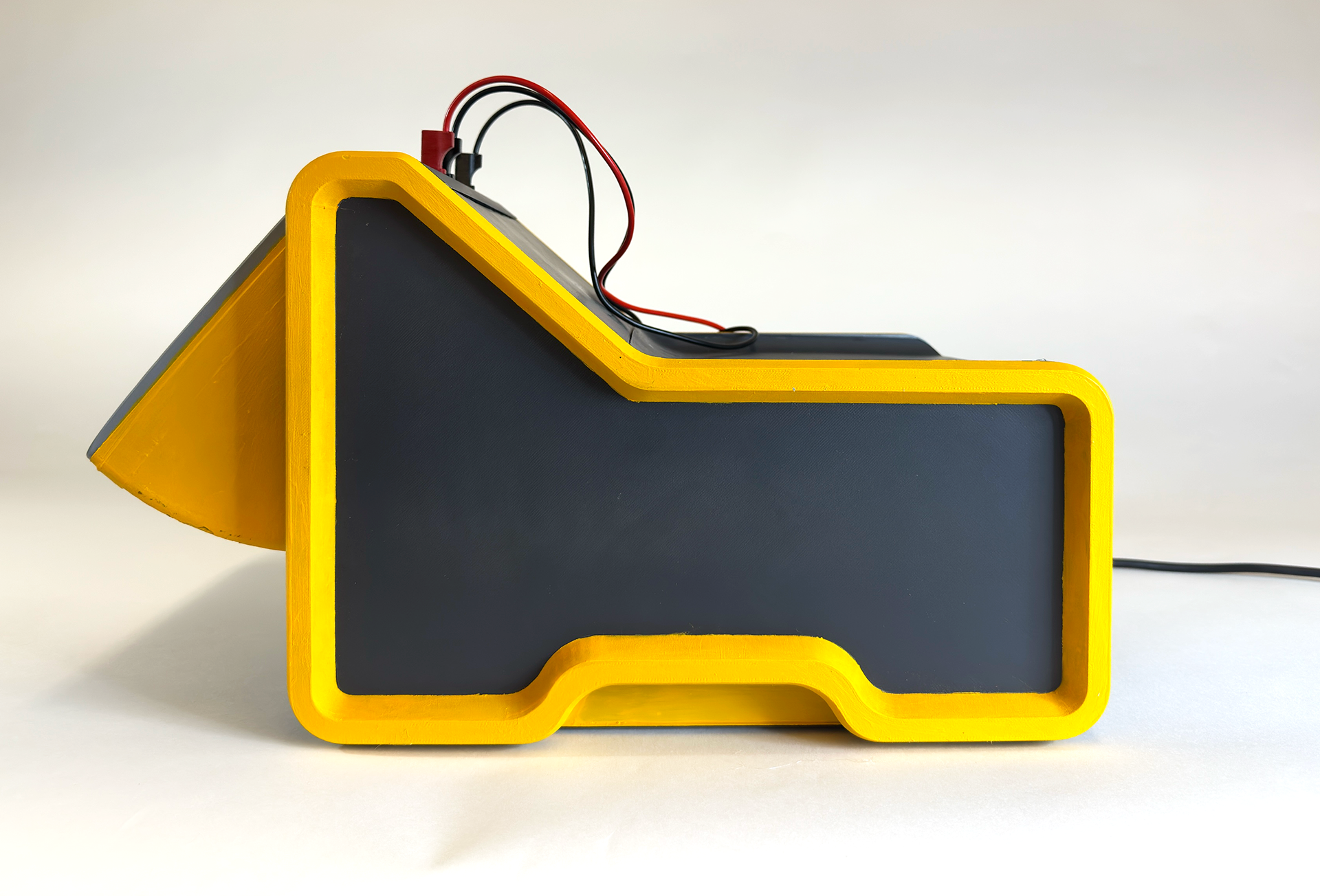

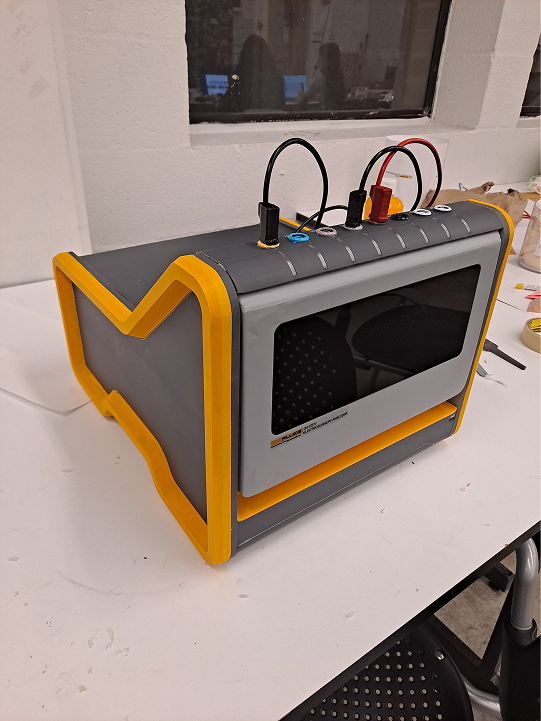

Final Sketches: We wanted an adjustable screen for different heights, a cable waterfall, and handles

QA-ES IV

The next part of our project was changing the Interface. In the hospitals they have to go through a work book and manually input all of the settings. We found a way to incorporate all of the tests for all of the different machines into our interface to streamline the process and increase user friendliness.

Here is a storyboard describing the use of the QA-ES IV.

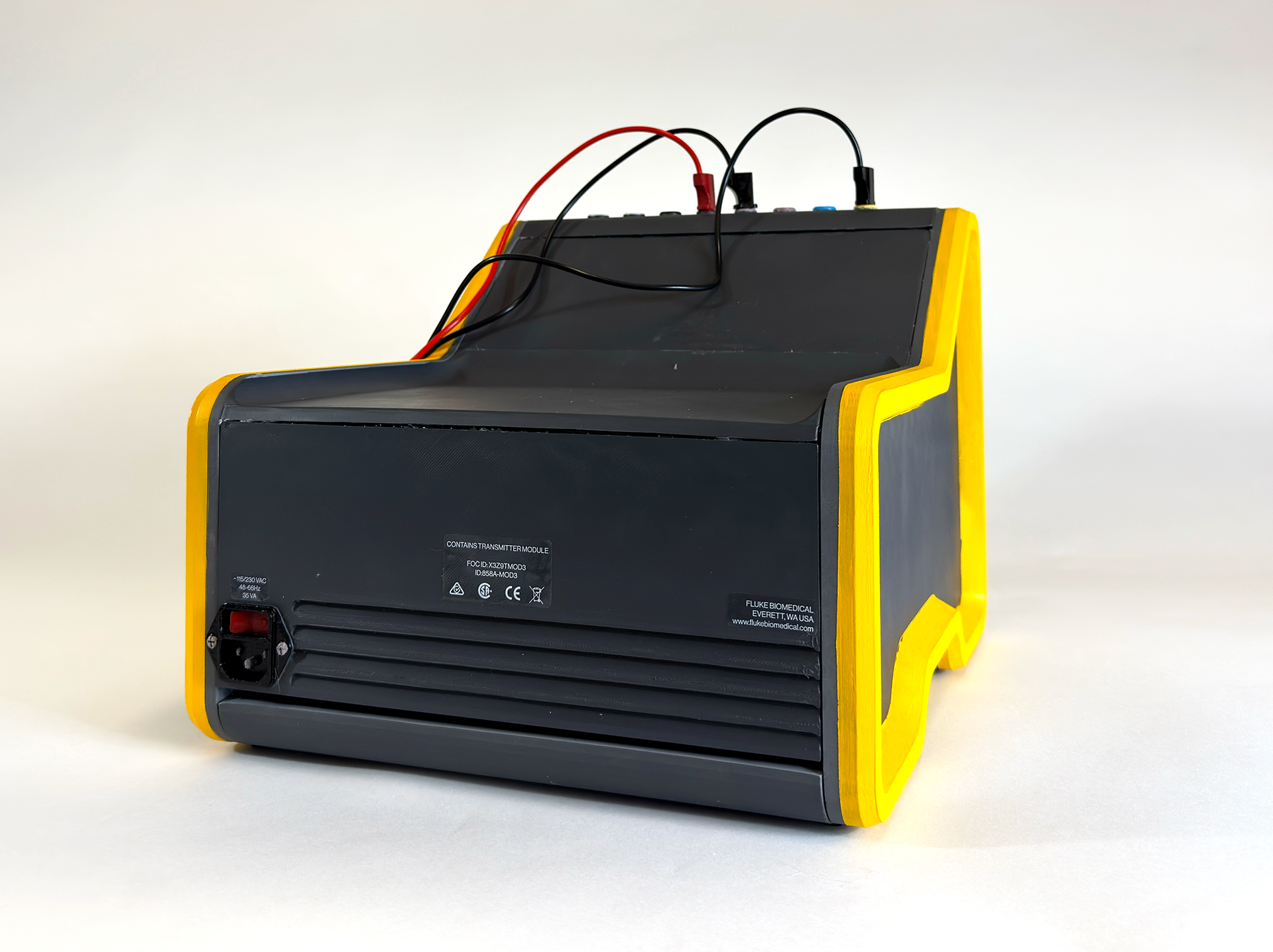

I was in charge of our final prototype. I was able to find a way to efficiently 3D print the body and paint it to make a high fidelity physical prototype. I was able to show off our light up ports and pop-out screen in a 1:1 prototype.

Here are prototype pictures.

Here are the process photos of the prototype.

Enjoy this animation we made!